Quality Control Systems

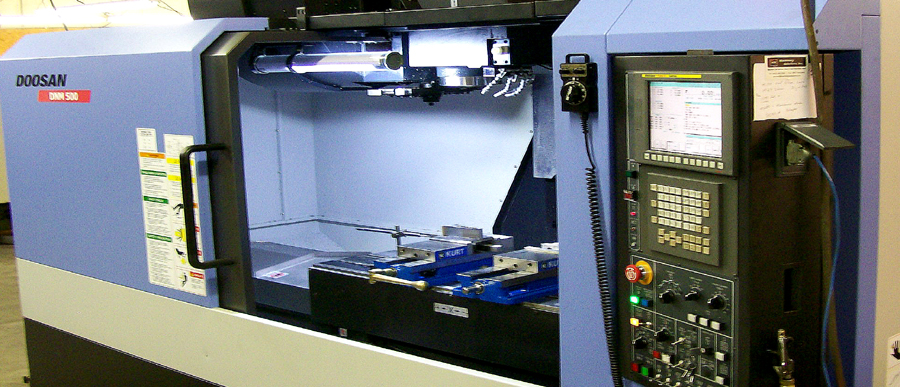

Investment at Belmont is not limited to production machinery, we have a fully air conditioned, dedicated inspection department with the very best inspection equipment available. A CNC controlled Co-ordinate measuring machine enables inspection of 3d surfaces, and once a part has been inspected the program can be recalled and repeated at any time by the operator.

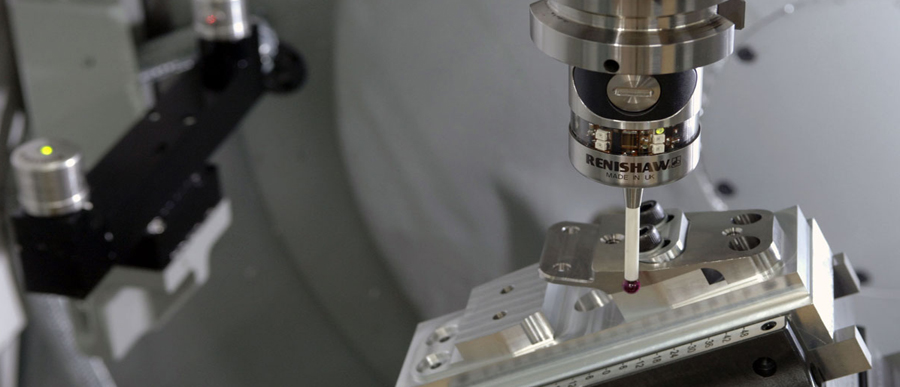

Our Mitutoyo FN905 High Accuracy model 3 Axis CMM also has a Renishaw MP10 motorised probing system, with full CNC probe changing facility and motorised 360° angle head. This machine is equipped with QCT Inspect 3D Software.

Complementing the High-Tech equipment is a Zeiss optical measuring machine, surface finish measuring equipment and an array of the more usual inspection tools, all calibrated to national standards at pre-defined intervals.

All manufacturing at Belmont is carried out under the control of our our BS EN ISO 9001: 2008 registered quality system, with everything ranging from supplier assesments and material purchase to contract review and final inspection being performed in a controlled and fully documented manner.

We were one of the very first companies in the UK to receive BSI accreditation, back in the days when it was named BS 5750 and our quality manual has been honed and refined over the years to suit us and a wide variety of customers. If you would like to see a copy of our quality manual, please contact our Quality manager.