Milling Services

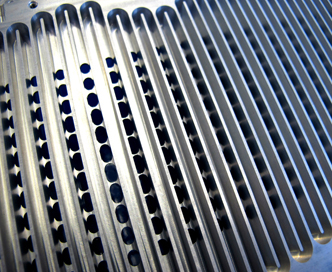

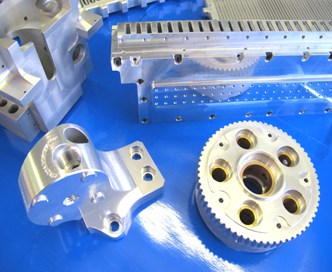

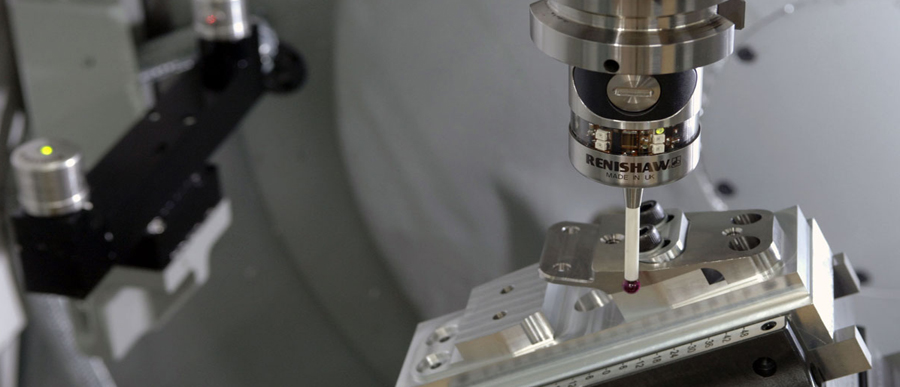

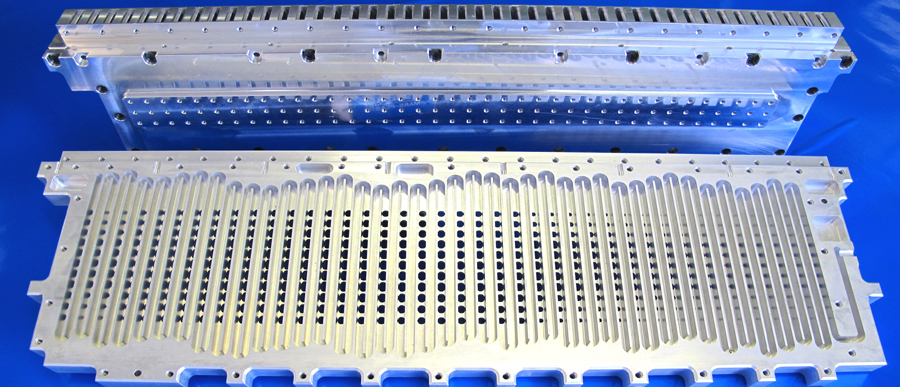

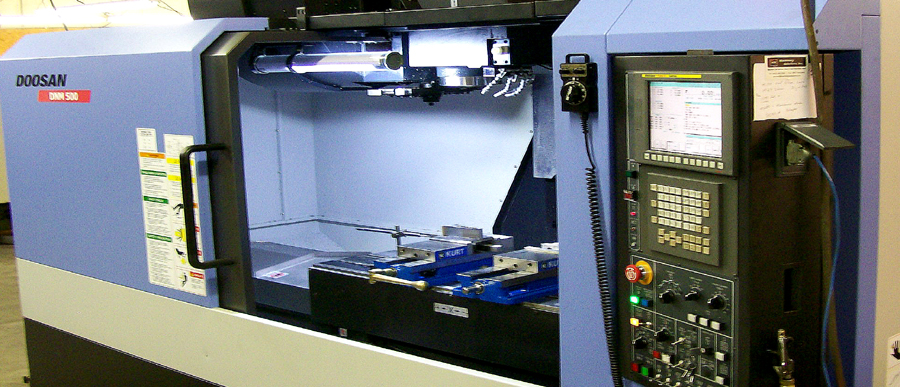

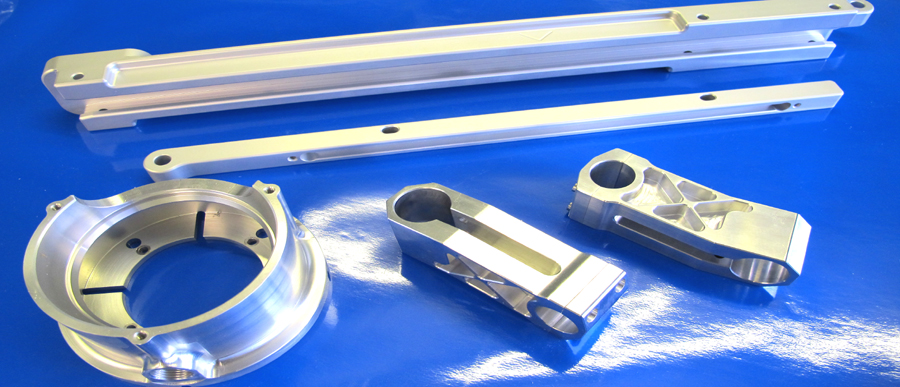

With substantial investment in CNC machinery, Belmont Engineering is able to offer a wide range of sub-contract multi axis CNC machining services. Continuing investment in the latest technology provides customers with a Vertical CNC Milling capability up to 1.5 metres in length together with CNC turning facilities up to 300 mm in diameter. Complimented by our CAD/CAM system to minimize programming and downtime, the shopfloor can provide a rapid response to customer's requirements. For customers without their own design team, our in house design facilities enable us to take your concept to final product. In addition to machined components we can also supply a range of sheet metal components and fabricated assemblies, to provide you with a one-stop-shop for your products and assemblies. Materials machined include Aluminium, Stainless steels, plastics and a range of exotic alloys. Our in house wet blast finishing plant (Vapour blasting) enables us to provide surface finishing to an un-matched standard, we can also provide graphic / logo etching (frosted glass finish) onto most materials including Aluminium, Steel, Glass and some plastics.